- 埃肯

- 产品

- 有机硅

- 用于纸张和薄膜涂层的有机硅

- 遮蔽胶带

用于遮蔽胶带的有机硅压敏胶

保护电子设备的有机硅压敏胶

用于电子产品和遮蔽应用中表面保护的高温有机硅压敏胶。

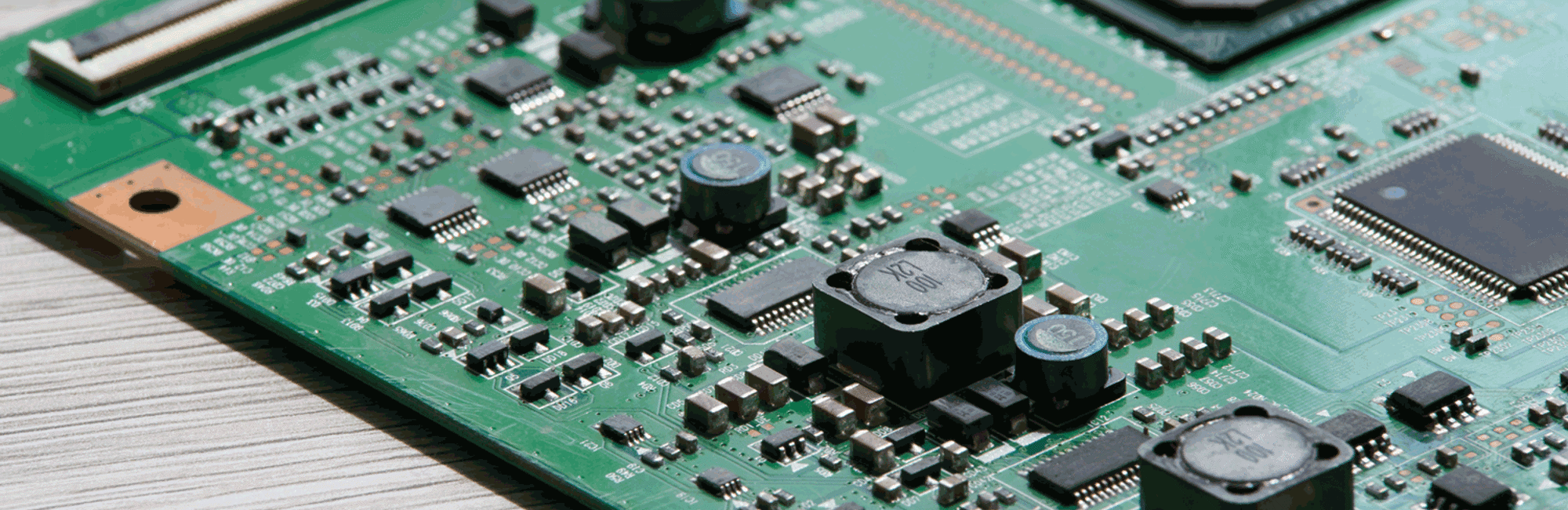

随着零件变得更精密、更小巧和更复杂,多年来在制造过程中遮蔽胶带的需求也不断发展。 制程中遮蔽和保护已在各种行业中广泛使用,从航空航天着陆到电路板上的微小连接,每种应用都要求遮蔽胶带能够承受更高的温度或更具腐蚀性的工艺。

所以需要安全可靠的解决方案在加工过程中保护敏感的电子组件,在粉末喷涂或金属化工工艺之前对加工好的物件进行遮盖时,制造商通常会选择有机硅遮蔽胶带。有机硅遮蔽胶带是自缠绕的粘性薄膜,通常涂在聚酯或耐高温的卡普顿聚酰胺薄膜上。所使用的压敏胶必须耐高温并且即使在不规则的表面上也必须具有出色的粘合力。它们必须在低表面能塑料,各种电路板材料,异金属或在化学侵蚀性环境中也能很好地工作。

遮蔽应用中使用的有机硅离型涂料有哪些主要性能?

Silcolease™有机硅压敏粘(PSA)能够满足胶带工程师所期望的所有关键性能要求:

- 可以粘附到各种基材上,即使在高温暴露后或高温暴露期间也可以移除不残胶。

- 流动性好,可粘附在不规则的表面上,从而可以很好地应对腐蚀性的化学浴和环境侵蚀

- 化学耐受性使其能够抵抗溶剂和化学暴露,例如印刷电路板(PCB)制造过程中的酸洗步骤,以保障敏感的电子组件(如PCB金手指)能够保持清洁免受污染

- 对焊接和金属涂覆的抵抗能力使其可满足PCB制造步骤和工艺的要求

- 较宽粘性和粘附力范围可根据不同的应用需求进行调整,而无需担心在加工过程中掉落或剥落

- 在大多数制造工艺中,稳定粘合可耐受高达270℃的温度,受保护的表面不会污染或变色

为什么选择埃肯作为有机硅压敏胶产品的合作伙伴?

- 我们的全球技术专家将协助您选择适合您应用的产品。

- 我们将在您最需要时提供培训、故障排除和技术帮助。

- 我们的知识和经验将使您更快地将产品推向市场。

- 我们与您合作,以个性化的方式为您提供有机硅解决方案。

埃肯的相关产品

Silcolease™有机硅压敏胶采用以下技术:

- 过氧化物硫化PSA

- 加聚反应PSA

联系我们

与全球领先的材料制造商携手,将您的企业提升到一个新的水平。